how does a double check valve work

This design inhibits backflow in a line. If the work is being performed on the vehicles air brake system or any auxiliary pressurized air systems make certain to drain the air pressure from all reservoirs before beginning ANY work on the vehicle.

Backflow Preventers At Commercial Properties Ccpia

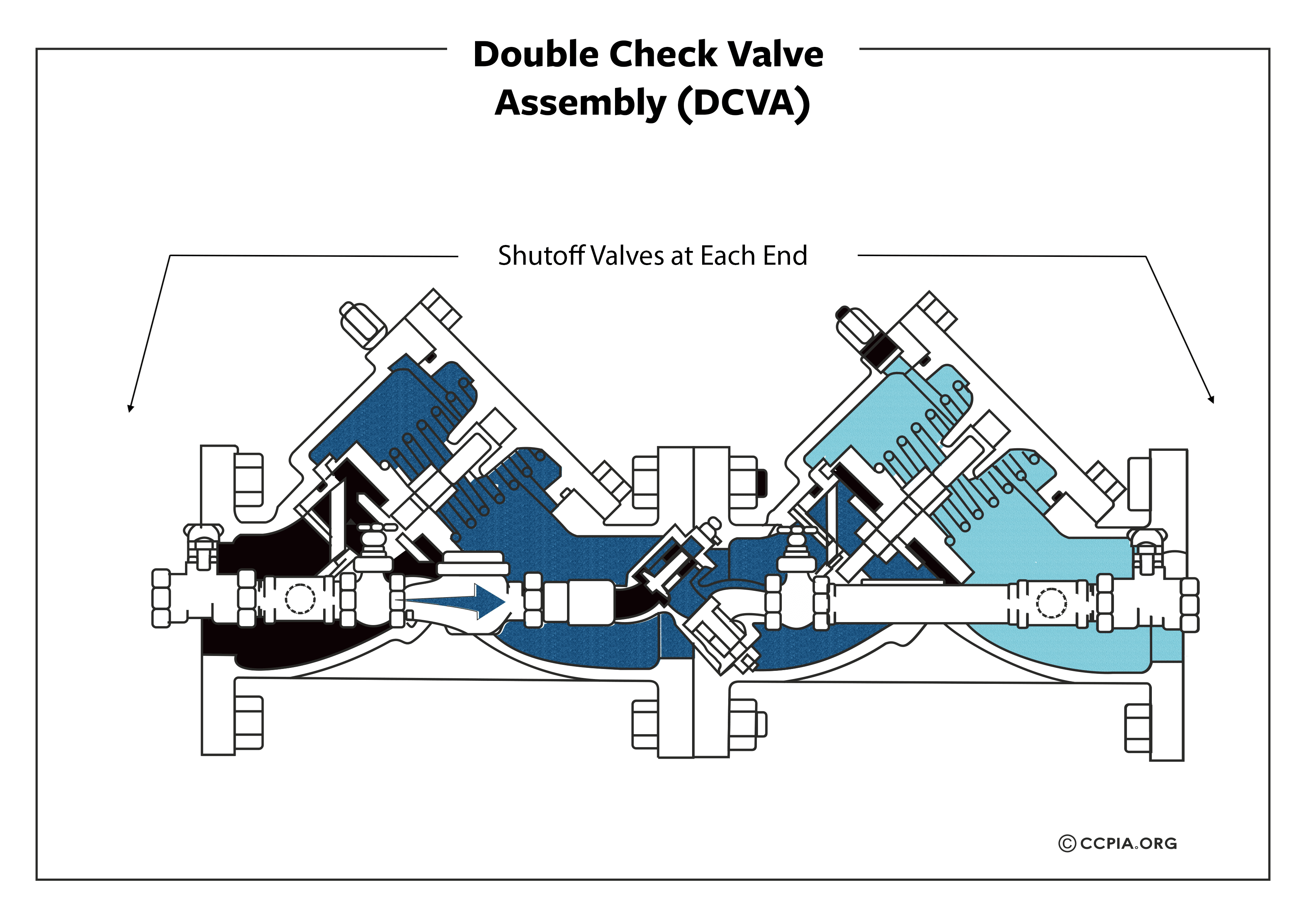

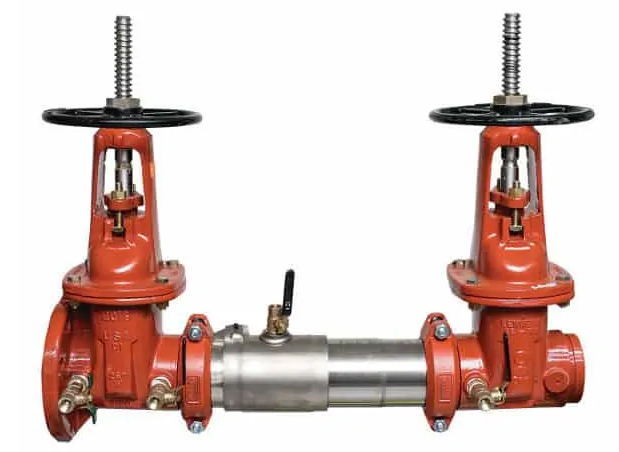

A double check valve or double check assembly DCA is a backflow prevention device designed to protect water supplies from contamination.

. The valves may be used for directing air flow for specific functions or to select the higher pressure of either of two sources of air as a supply source. How does a check valve work. Skip to the end of the images gallery.

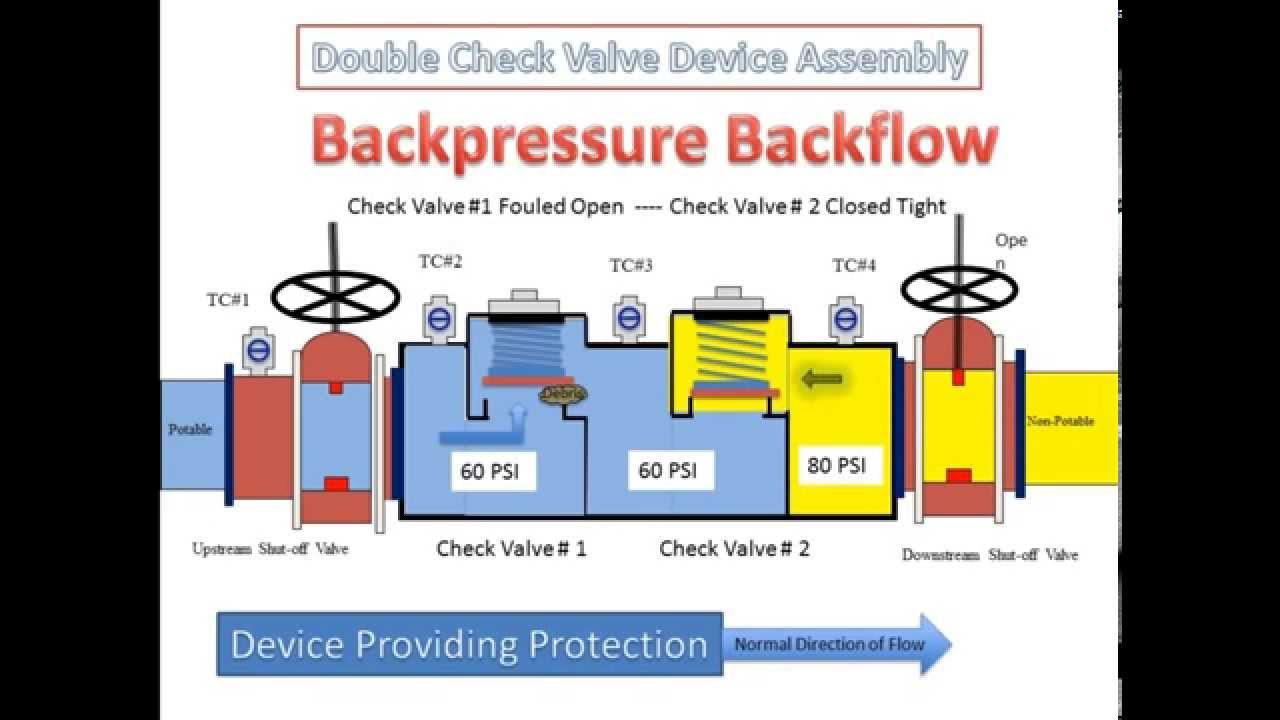

Check valves are flow sensitive and rely on the line fluid to open and close. A double check valve is used in the air system when a single function or component must receive air from or be controlled by the higher of two sources of pressure. A backflow preventer is used in high-risk scenarios and is designed to fully protect potable water with its fail-safe design whereas a check valve is used in low-risk situations and stops backward water flow but lacks the same fail-safe components.

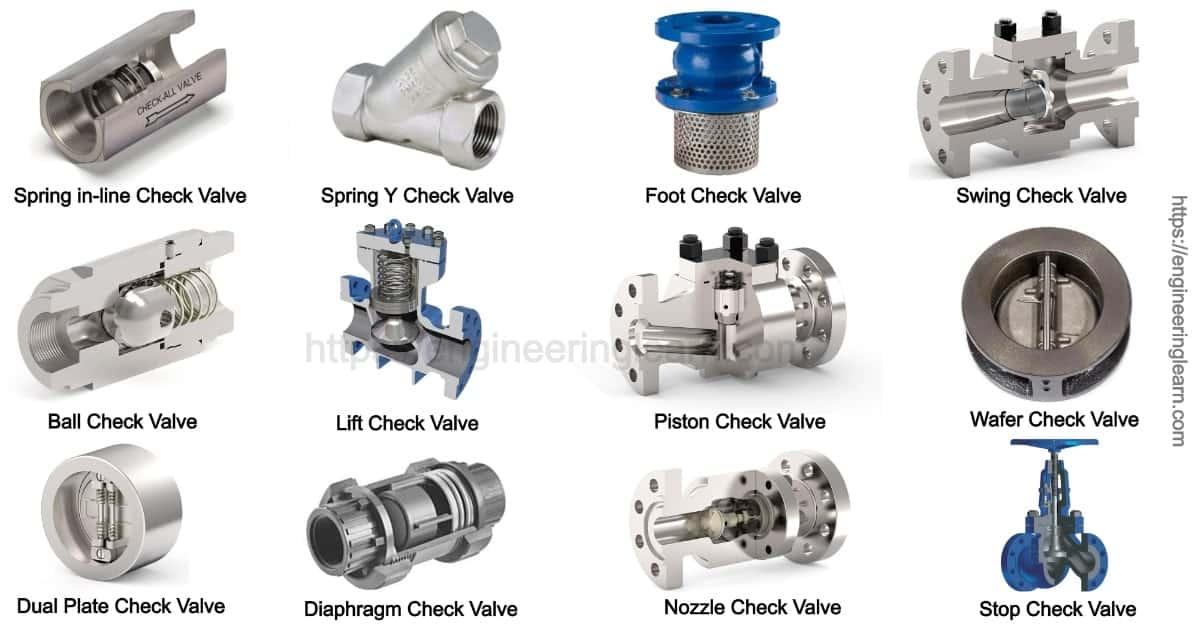

This valve is similar to the swing check and a little better in terms of closing because of the coiled springs that assist the two cantilevered doors in closing more quickly. Check valves permit flow in one direction only and close automatically if flow reverses. Once the system reaches the cracking pressure or the minimum upstream pressure needed for the valve to operate the disc will lift and allow the fluid to pass through.

Double Check Valves DCV DCVs are specifically designed to prevent backflow in fire sprinkler systems. Stayflow Selection and Service. The double check valve only allows water to flow through in one direction therefore preventing backflow of potential contaminants.

Please call 8776543837 for availability. The cracking pressure is affected by the force required to open the check valve which may depend on the tightness of the spring or the weight of a gravity-operated flap. While overall system usage plays a significant.

Check valves are controlled based on a systems flow velocity. To install simply push the valve fully on to the pipe. It has been proven that this is not the best choice when faced with water hammer though they will perform better than a swing check valve.

If the vehicle is equipped with. The Bendix DC-4 double check valve is used in an air brake system to direct a flow of air into a common line from either of two sources whichever is at the higher pressure. They require a higher pressure on the input side of the valve than the output side to open the valve.

When the pressure is higher on the outlet side or the input side pressure is not high enough the valve will close. Because of their simple design check valves generally operate without automation or human interaction and instead rely on the flow velocity. This is the precise upstream water pressure at which the valve cracks open allowing a measurable flow of fluid through.

DC4 Double Check Valve. They are entirely automatic in action depending upon pressure and velocity of flow within the line to perform their functions of opening and closing. The internal disc allows flow to pass forward which opens the valve.

Most Hattersley swing check valves can be installed in horizontal or vertical upward flow piping. Backflow Preventers and Check Valves differ primarily in their application. Ad Dual Disc Check Valves in Wafer Globe Lug Styles Iron Steel Stainless.

If the fluid pressure decreases or if the flow direction starts to reverse the disc will automatically close the valve to keep fluid from flowing through. Double-Door Check Valve. This video illustrates how a Double Check Valve Backflow Prevention Assembly functions.

Skip to the beginning of the images gallery. Should the need arise to demount the connection push the collet towards the body of the fitting and pull the pipe to release. The mainstay for normal fire protection applications DCVs feature an inlet upstream shutoff valve two independently operating spring-loaded check valves usually inside a single valve body four test cocks and an outlet downstream shutoff valve.

A check valve relies on a pressure differential to work. A clapper hangs from a hinge clapper shaft or pin mounted to the underside of the bonnet. Check valves also known as nonreturn or one-way valves enable fluid to flow one way in a pipeline.

Comparison Between Swing And Dual Plate Check Valve Download Scientific Diagram

Hydraulic Pilot Operated Check Valves Hydraulic Repair Schematic

Introduction To Check Valves The Process Piping

Types Of Check Valve Function Application Non Return Valve Engineering Learn

How Non Return Valves Work Plumbing Tips Youtube

The Importance Of Check Valves In Hydraulic Systems

How Do Check Valves Work Spec Sense Youtube

Water Quality In Your Home Single And Double Check Valves Youtube

How Does A Backflow Preventer Work

How Does A Backflow Preventer Work

Backflow Preventer Vs Check Valve What S The Difference Linquip

Backflow Preventers At Commercial Properties Ccpia

Introduction To Check Valves The Process Piping

What Is A Check Valve And How Does A Check Valve Work Empowering Pumps And Equipment

What Is Double Check Valve What Does Double Check Valve Mean Double Check Valve Meaning Youtube